- Monday to Saturday

- Mumbai-Maharashtra, India

- info@airzen.in

Our modular cleanroom is a prefabricated, customizable cleanroom solution designed for flexibility and ease of installation. Unlike traditional cleanrooms, modular cleanrooms are constructed using prefabricated panels and components that can be quickly assembled on-site, making them ideal for industries requiring controlled environments, such as pharmaceuticals, electronics, biotech, and healthcare industry.

Modular cleanrooms can be easily expanded, reconfigured, or relocated to accommodate changes in production needs or floor space.

Prefabricated panels and components reduce construction time and minimize disruption to facility operations.

Designed to meet industry-specific cleanroom standards (ISO, GMP, FDA) and customizable for specific cleanliness levels.

High-quality, non-shedding materials are used, often including stainless steel, aluminum, or powder-coated steel, with cleanroom-grade wall and ceiling panels.

We design the series of cleanroom Wall & ceiling Panel stems for the most stringent medical research and aspetic process applications. Our Wall Partition System is available in both Progressive and Non-Progressive types, crafted to meet diverse cleanroom configurations. Panels are designed with integrated PVC conduits to house electrical cables.

Our modular cleanroom of choice is used in Biomed, Life science, Medical device, Pharmaceutical proocessing. Our Modular Wall and ceiling systems offer significant performance advantages over tradiational clean facility solutions.

A modular cleanroom door is designed for controlled environments, offering durability, cleanliness, and compliance with industry standards. Available in materials like stainless steel or powder-coated steel, these doors feature a flush-mounted design, airtight seals, and optional interlocking mechanisms. Customizable in size and available in manual or automatic options, they integrate seamlessly with modular cleanroom systems to maintain contamination control and support efficient workflow.

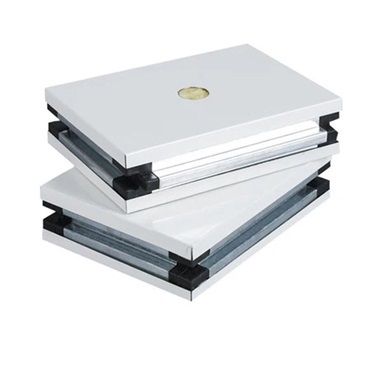

Modular Cleanroom Ceilings are precision-engineered to ensure a contamination-free environment while offering flexibility for cleanroom configurations. These ceilings are constructed from durable materials like powder-coated or pre-coated galvanized iron (PCGI), aluminum, or stainless steel and are designed to meet ISO and GMP standards. These ceilings provide a robust, easy-to-maintain solution for creating highly controlled environments.

Cleanroom Flooring is designed to provide a seamless, durable, and contamination-resistant surface for controlled environments. These floors are constructed using materials like epoxy, vinyl, or polyurethane, ensuring a non-porous and easy-to-clean finish that meets ISO and GMP standards.

More precisely known as return air risers, which are used to collect the return air in a specific manner to maintain a perfect laminar flow.